Lenze mechatronics PVT LTD

Booth number: P-20c

www.lenze.com

About us

Lenze Mechatronics Pvt. Ltd., a fully owned subsidiary of Lenze SE, Germany, is operational from the year 2005. Lenze is present almost all over the world with a number of manufacturing plants and various Assembly units. For its Indian operations, it is headquartered in Pune. It has a sales office, an assembly center, a Service Centre and a software development centre in Pune. It has branch offices in Ahmedabad, Bengaluru, Coimbatore, Delhi, Hyderabad, and Kolkata. It has the Lenze Automation Competency Centre (LACC) in Kolkata.

Lenze is known all over the globe for its pioneering services in the field of Drive Engineering with many innovative solutions catering to specific applications for various Industries. We provide system solutions including controller-based automation as well as mechatronics solutions. The basic product range of Lenze includes Electrical Motors (of various types), Gearboxes, Gear Motors, AC Variable Frequency Drives, Servo Drives, Servo Motors, Motion controllers, Visualization, Automation Products, and digitalization.

Lenze has a global footprint in Airport Projects. Lenze's drive and automation solutions for airport logistics are used primarily in baggage and freight logistics. Lenze has various customers present all across the globe. Some of the reference global airports using Lenze solutions are Helsinki-Vantaa (Airport storage and transport system), Istanbul Airport (Cargo Handling systems), and Toscana Aeroporti (Baggage Handling System). In India, Lenze has provided solutions in Dehradun, Hyderabad, and Kolkata airports in Baggage Handling systems.

Lenze has provided standard geared motors, smart motors ( - can operate at multiple speeds), Motec(- decentralized frequency inverter), and i500( frequency inverters) in worldwide projects amongst other solutions in its portfolio. Lenze has a world-class aftersales services capability. Lenze has strong services as well as an applications team. Lenze supports its customer with comprehensive support in the digital transformation process to improve the productivity of the machines. We see ourselves as a one-stop solution partner and apply all our know-how to develop the best possible package in partnership with the client. The project benefits include scalable hardware, modular software, and brainware.

Address

Plot I-19, Gat 1898, Khed to Pabal Road, Kanhersar Taluka – Khed

410505 Pune

India

E-mail: suman.lahiri@lenze.com

Phone: +91 992 3001626

Internet: www.lenze.com

Contact person:

Mr Debasis Nandi

President

E-mail: debasis.nandi@lenze.com

Products & Services

Inverters

Configurable for all requirements. Whereas inverter applications are extremely varied, our precisely tailored and uniform product range is much easier to handle. A range tailored to meet your exact needs– from basic movements and positioning tasks to servo applications. Our devices are reliable, meet strict quality requirements and can be easily adapted to suit your specific requirements.

Inverters – Decentralized

Inverter Drives i550 protec

Suitable for wall or machine mounting with pluggable connection system. Power range: 0.37 to 22 Kw. Particularly suitable for: travelling and conveyor drives in the field of intralogistics, fans, and pump drives. i550 protec frequency inverter (lenze.com)

Inverter Drives 8400 protec

Suitable for wall mounting with pluggable connection systemPower range: 0.75 to 7.5 kW (2.4 to 16.5 A). Particularly suitable for: scissor-type lift tables in the field of intralogistics and in the automotive industry. 8400 protec frequency inverter (lenze.com)

Inverter Drives 8400 motec

Mounted directly on the motor or to the wall. Power range: 0.37 to 7.5 kW (1.3 16.5 A). Particularly suitable for: travelling and conveyor drives in the field of intralogistics, fans and pump drives. 8400 motec frequency inverter (lenze.com)

i550 Motec Frequency Inverter

The i550 motec frequency inverter in the power range of 0.37 to 45 kW for motor and wall mounting in protection class IP66 is the optimal decentralized drive solution. Fast mounting and easy commissioning thanks to user-friendly tools as well as connections for commercially available connectors are the focus of this inverter. Parameters, drive behavior and usability correspond to our proven frequency inverters. Rounded off by high energy efficiency, we thus offer a modern and sustainable drive solution. The requirements of the Ecodesign Directive, Standard EN 50598-2, are met. Application areas: Conveyor drives, traveling drives, winding drives, hoist drives, extruders, packaging machines, pumps, fans, etc. i550 motec frequency inverter (lenze.com)

Servo inverter i950

The new intelligent i950 as a compact servo inverter, which covers many applications from modular machine concepts up to complex multi-axis systems. Increase cycle rate up to 20%, integrated control loops in 62.5 us, position angular accuracy down to 2 angular seconds, Real-time data directly for cloud-based solutions, Output current: 2.4-212 A (0.37 to 110 kW) (i950 cabinet servo inverter (lenze.com)

Servo inverter 9400 HighLine

Impressive results for demanding machine tasks and single-axis or multi-axis applications. Inverters for controlled dynamic motion. Output current: 1.9 to 695 A (0.37 to 370 kW). Particularly suitable for: processing of continuous material in the packaging industry, perforating paper webs in the printing industry, winding in the textile industry, storage technology in the field of intralogistics. (9400 HighLine servo inverter (lenze.com)

Servo Inverter 8400 Topline

Easily achieve impressive dynamics and accuracy Inverters forcontrolled, dynamic motion. Output current: 1.3 to 89 A (0.37 to 45 kW). Particularly suitable for: flying saws and cam discs in the packaging industry, synchronized drives in the printing industry. (8400 TopLine frequency inverter (lenze.com)

Servo Inverter i700

New inverter for controlled dynamic motion. Output current: 2.5 to 32 A (0.75 to 15 kW). suitable for: handling and packaging machines and robotic applications.

(i700 cabinet servo inverter (lenze.com)

Frequency Inverters:

Frequency Inverter i510

The basic i510 inverter covers a power range from 0.25 to 15 kW. Slimline design from 60 mm x 130 mm: fits into every control cabinet. This reliable drive is ideal for conveyor, travelling, and winding drives, for pumps and fans and many other machine tasks. ( i510 cabinet frequency inverter (lenze.com)

Frequency Inverter i550

The universally applicable i550 cabinet from 0.25 to 132 kW have the same DNA but differ in functionality and are optimized for a good price/performance ratio. Optionally with "Safe Torque Off” (STO) with SIL 3 (ISO 13849-1 (EN 954-1)) and Performance Level e. Flexibility: Get the i550 as a complete device or in individual components (Power Unit, Control Unit and Safety Unit). Particularly suitable for: pumps and fans, conveyor, travelling, winding, former, tool and hoist drives.

i550 cabinet frequency inverter (lenze.com)

Frequency Inverter 8400 HighLine

Inverters for easily controlled motion and positioning. Power range: 0.37 to 45kW (1.3 to 89 A). Particularly suitable for: rotary indexing tables or warehousing systems in the field of intralogistics, bag form fill and seal machines in the packaging industry. 8400 HighLine frequency inverter (lenze.com)

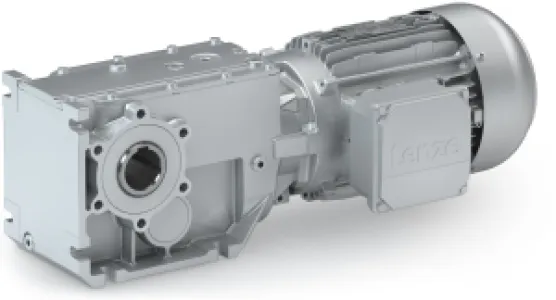

Gearboxes and geared motors

Our gearboxes and geared motors can be used in a wide range of applications and their functions are scalable to your specifications. Because of the basic modular concept and their high-power density, they can even be integrated into extremely small sizes. Our range of products includes commonly used industrial geared motors with a power range of up. Our gearboxes' high efficiency levels and the efficiency of our motors assure you receive an optimized drive package that meets the highest demands.

Planetary gearbox g700-g800 –

The g7x0 planetary gearboxes and bevel planetary gearboxes as well as the low backlash g8x0 extend the range of mechanical drives with high-quality servo drives. Planetary gearboxes have a high overload capacity, are torsionally stiff and ensure low backlash of up to 3 angular minutes. Coupled with our servo motors they form a compact and powerful drive unit. The gearboxes are available with a torque of up to 1000 Nm. g7x0-P planetary gearboxes (lenze.com) g8x0-P planetary gearboxes (lenze.com)

Shaft-mounted helical gearbox g500-S –

In combination with AC and servo motors, our shaft-mounted helical gearboxes form a compact and effective drive unit. The low level of backlash of the gear teeth ensures highest precision. In addition, they can also distribute the power output and torque via an output shaft on both sides. The gearboxes are available in 2, 3, and 4 stage versions with a torque of up to 19,000 Nm and a ratio of up to i=4300.

g500-S shaft-mounted helical gearboxes (lenze.com)

Helical gearbox g500-H-

In combination with AC and servo motors, our helical gearboxes form a compact and powerful drive unit. They are rugged in design and feature high permissible radial forces, closely stepped speed reduction ratios and minimum backlash. The gearboxes are available as 1 and 2, 3, and 4- stage versions with a torque of up to 14,000 Nm and a ratio of up to i= 3,250. g500-H helical gearboxes (lenze.com)

Bevel gearbox g-500B-

Our bevel gearboxes are a showpiece for lightweight engineering. They are also highly efficient and are equipped with wear free teeth. Together with three-phase AC motors and servo motors, they form and efficient and compact drive unit. They are available as a 2, 3, and 4 stage version with a torque of up to 20,000 Nm and a ratio of up to i=2,950. ( g500-B bevel gearboxes (lenze.com)

Motors

Drive technology is subject to a multitude of different requirements, which must be catered to on an individual case-by-case basis. Our comprehensive range of dynamic, compact, scalable and overload-resistant motors allows you to find the perfect motor for your requirements. Motors from Lenze have repeatedly proven their worth day in, day out.

Servo Motors:

MCS synchronous servo motors –

Servo synchronous motor for precisely controlled motion. Particularly suitable for: application that require high dynamic performance, precision, and minimal dimensions. Torque range: 0,5 to 190 Nm (0.25 to 15.8 kW). MCS synchronous servo motors (lenze.com)

m850 synchronous servo motors- medium dynamics in compact design, The compact m850 synchronous servo motors for positioning, robotics, packaging technology and handling system applications. Torque range: 4.8 Nm to 200 Nm (2 to 9.2 kW). m850 synchronous servo motors (lenze.com)

MCA asynchronous servo motors-

Servo asynchronous motor for precisely controlled motion. Torque range: 2.0 to 1,100 Nm (0.8 to 53.8 kW) MCA asynchronous servo motors (lenze.com)

Three-phase AC motors:

MF three-phase AC motors –

Energy-efficient, inverter-optimized three-phase AC motor for variable motion. Power range: 0.55 to 22 kW. Particularly suitable for tasks that demand large setting ranges with minimal sizes. MF three-phase AC motors (lenze.com)

m550- H three-phase AC motors –

The IE2-high efficiency m550-H motor covers the power range from 0.12 to 0.55kW.

m550- P three-phase AC motors –

The IE3-premium efficiency m550-P motor covers the power range from 0.75 to 22 kW. IE2/IE3 m500 three-phase AC motors (lenze.com)

m300 smart motor-

m300 lenze smart motor for main operation, handle the selectable multiple speed, start-stop application hence no need of VFD for basic needs in horizontal conveying, wide RPM range i.e., 500 to 2600, 4 times high starting torque than DOL, soft start / stops. Lenze Smart Motor m300

Controls

Automation - a true system

Controllers C750 – IT meets OT

The c750 control unit brings together the worlds of OT (Operational Technology) and IT (Information Technology). For this purpose, the PLC is extended by the functionality of an industrial PC. Windows-based applications can be directly executed in the Open System area of the controller and communicate with the PLC area via a secure connection. A separate industrial PC is not required. c750 controller (lenze.com)

Controller C5XX –

This new product range will enable you to easily realize high-end control applications, such as printing machines with many printing units or picker lines with multiple robots. Using the software modules provided through FAST, this makes it possible to realize modern and modular machine controls. Supports industry standards such as OPC UA (DA Server) and EtherCAT. c520 controller (lenze.com) c550 controller (lenze.com)

Controller 32XX C –

The Controller 3200 C with Atom processor offers everything that an automation specialist desires from a strong partner: a compact and especially robust design, large power reserves and a comprehensive set of features. Highly deterministic backplane bus with precise 1 μs time stamp. 3200 C controller (lenze.com)

Controller C300 –

the precisely tailored Controller c300 takes responsibility for all your control tasks. It focusses primarily on basic control (PLC) and motion tasks. c300 controller (lenze.com)

Controller p500

We have taken yet another step towards creating an easier future with the p500 -a perfect combination of our maintenance-free panel controller, logic (PLC), motion and visualisation in a single device. It is ideally suited for use as a control and visualisation system within controller-based automation set-ups for applications with central motion control or as a visualisation device within a drive-based automation system. p500 controller (lenze.com)

Controller p300

Based on the Panel Controller p500, the new p300 fits seamlessly into our platform which is built on a consistently modern system architecture. It combines logic (PLC) and visualisation in a compact device and is ideally suited to machine applications which only require a low processing power. available in sizes 10.9 cm (4.3"), 17.8 cm (7") and 26.4 cm (10.4"). p300 controller (lenze.com)

Safety Controller c250-S

With the expansion of the controller software to include the Safety Controller c250-S a complete automation solution is provided for safety engineering and control and drive tasks. Topped with the safety I/O module. c250-S safety controller (lenze.com)

I/O system 1000

At the very first glance, the product family impresses with the narrow design of the I/O modules, which offer space for 8 connections. They only require 12.5 mm of space on conventional DIN rails. (I/O system 1000 (lenze.com)

Visualization

IPC v800-C

The powerful industrial PC v800 cabinet for integration into the machine housing. All the devices are equipped with the most up-to-date, glove-friendly multitouch glass sensors, and the operating program can be created intuitively with the engineering software VisiWinNET®. Highlights: High-resolution displays from 13.3" to 24",

non-rotating mass storage device,

Front panel IP65 degree of protection.

v800-C industrial PC (lenze.com)

IPC v800-P

A high degree of standardization guarantees maximum availability and protection of software investments over a long period of time.

Highlights: Appealing and elegant device design, High-resolution full HD displays in 17.3" and 24", Based on hygienic design, no visible screws, IP65 degree of protection, easy to clean, Individualization via optional switch box, VisiWinNET® for designing intuitive visualizations. v800-P industrial PC (lenze.com)

Monitor v200-P

The v200 monitors depict the visualisation created on the upstream IPC. A visually uniform line from the industrial PC to the monitor enables uniform machine design. Highlights: High-resolution full HD displays in 17.3" and 24.0", Standard HDMI or DisplayPort connection, Optional mounting up to 100m from control cabinet PC via integrable Extender, Complies with hygienic design guidelines, no visible screws, IP65 degree of protection. v200-P monitor (lenze.com)

Web Panel v450

Aesthetic machine visualizations in modern design, which can also be operated intuitively, are becoming increasingly important. Our web-based offer from the EASY UI Designer project planning tool and the FAST UI Runtime on the c520 and c550 controllers together with the v450 web panel offer a solution for such visualizations. Highlights: 7”, 10.1”, or 15.6” TFT color display - three sizes for your application, Multitouch capable glass display- suitable for modern operating modes, Protection class IP67 – Installation on the field or on the machine, Supply via power-over-Ethernet (PoE). v450 web panel (lenze.com)

IoT Gateways

IoT Gateways X5xx

Controlling is sometimes quite easy – in machine automation, the cloud-based Remote Service Platform x4 shows how it works. With this platform, machine and plant monitoring can be brought into a cloud environment without specific IoT knowledge. It allows access from anywhere with Internet enabled devices. Functions such as data dashboards and alarm functions are available, e. g. with powerful condition monitoring services. Highlights: Gateway via LAN, Wi-Fi or 4G for easy, integration into the system periphery, Connect your machine to the cloud within just a few minutes, Create your personalized dashboards, Data controlling in the cloud ensures secure information, e.g., through two-factor authentication, Using the Remote Service Platform is very easy via the available IoT Gateways x510, x520, x530 and x540. IoT gateways (lenze.com)